Description

REVO INTERCOOLER

AUDI RS3 8V2 & 8Y

The Revo Intercooler utilises unique design features to lower intake air temperatures, minimise pressure drop and allow the engine to produce impressive power and torque with Revo Software. The unique end tank profile promotes internal laminar flow by decreasing turbulence and increasing airspeed into the bar and plate core. This enhances charge air cooling giving you access to more power throughout the rev range.

The limitations of the stock intercooler were apparent throughout testing. The stock part consistently struggled to manage charge air temperatures, especially on vehicles with performance software. The Revo Intercooler has been designed to improve on every restrictive element of the stock cooler, enhancing cooling efficiency by lowering intake air temperatures by up to 38ºC vs. the Stock intercooler, allowing you to drive harder, for longer.

KEY FEATURES

- Bar & Plate Core Design

- Fully Cast End Tanks

- Reinforced Mounting Brackets

- Intercooler Pipes Included

- Up to 53% increase in the frontal surface area

- Up to 38% increase in core volume

- Fits with OEM Crash Bar

INCREASED CORE VOLUME

The Revo Intercooler was built around a simple principle; create a cooler that can keep up with your power demand. Designed from the ground up, the Revo Intercooler has a 38% larger core volume than the OEM part and offers perfect fitment by Utilising the volume of unused engine bay space behind the OEM (US and ROW) crash bar.

INCREASED FRONTAL AREA

Due to the custom-designed end tanks, the frontal area of the intercooler has been increased by a massive 53%. Offering the best balance between increased performance and acceptable part clearance, whilst also minimising pressure drop.

END TANK DESIGN

The Revo end tank geometry maintains the largest possible cross-sectional flow area to and from the core. With a cast interior surface finish, the Revo end tanks allow air to flow freely without obstructions. The design has been balanced between core width and optimal tank profile design. End tanks play an important part in maintaining pressure and work in harmony with the core to promote airflow, the Revo end tanks are designed to offer the optimal balance between both of these key features.

BAR & PLATE

Designed with a bar and plate core to maximise the efficiency of heat transfer, the pressure drop is also controlled as the air meets less resistance compared to that of a tube and fin alternative. The Revo Intercooler also features carefully specified fin geometry to maximise cooling properties while minimising flow restriction. The ambient core side utilises louvred fins to slow ambient airflow which improves heat transfer, while the charge core side features an offset internal fin design to balance surface area and air resistance to minimise pressure drop.

INTERCOOLER PIPE UPGRADE

Supplied with an upgraded aluminium charge and silicone throttle pipes. The increased diameter pipework ensures the maximum performance by increasing system volume by over 27%. The internal diameter of each silicone is precisely matched to the outer diameter of the ribbed inlet and outlet connections along with a unique Flush Fit design, allowing a smooth transition between components.

RESEARCH AND DEVELOPMENT

All Revo products are designed in-house using the latest 3D printing technology, CAD and CFD software. Every product is rigorously tested utilising an in-house Hub dyno and Revo data acquisition software. The Revo intercooler minimises turbulence while maximising heat transfer, promoting cooler air temperatures and low-pressure drop. This helps retains power and torque throughout the rev range as highlighted during controlled Dyno testing.

The Revo Intercooler was tested in-house to compare the performance against that of the stock Intercooler. First tested on a vehicle running the OEM Intercooler with Revo software, a Revo carbon series air intake system and Milltek downpipe exhaust, the Revo Intercooler and pipes were then installed and tested in the same controlled environment to highlight the benefits of enhanced cooling.

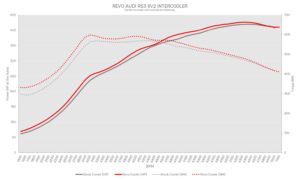

PERFORMANCE DATA

Showing the last of four consecutive dyno runs, the efficiency of the Revo Intercooler over the OEM RS3 intercooler is highlighted. With peak gains of +17 HP (hubs) & +43NM Torque, along with increased performance throughout the entire rev range. The stock intercooler struggles to effectively function in comparison to the Revo Intercooler which remained consistent throughout.

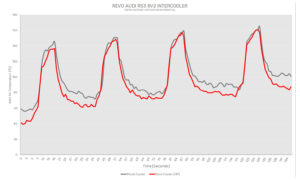

INLET TEMPERATURE

This is a metric used to confirm that testing on the RS3 8v.2 2.5TFSI Intercooler. This is used to show that the air temperatures going into the intercooler were similar for each test, confirming that outlet temperatures shown in the following graphs are purely down to differences in intercooler design/construction. As can be seen, the “dwell” between testing runs is higher with the OE setup vs. Revo. While this initially seems less than desirable for comparable data, this temperature difference is actually down to the thermal mass differences between setups; indicating that the Revo kit can absorb much larger amounts of heat more efficiently than the OE setup, yet the Revo intercooler produced the lower outlet temps proving the cooling efficiency.

OUTLET TEMPERATURE

This is the main performance metric to illustrate that the Revo intercooler far exceeds the stock unit. A strong indication that the Revo intercooler is extremely resistant to heat soak and could likely continue for ten more sequential dyno runs before any intake temperature-related issues arose. The graph illustrates the increased cooling performance of the Revo intercooler vs RS3 intercooler over all four runs. The Revo Intercooler provided a massive 38.2°C max and 18.23°C average intake air temperature reduction across the six back to back full gear dyno runs.

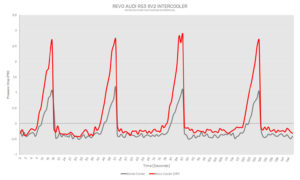

INTERCOOLER PRESSURE DROP GRAPH

Pressure drop is an important factor when it comes to choosing an Intercooler. The Revo solution features custom cast end tanks to evenly distribute air over the core. This graph highlights that even with massive core size difference there is only a 0.34psi pressure drop in comparison to the stock intercooler, ensuring engine response and minimised turbo lag